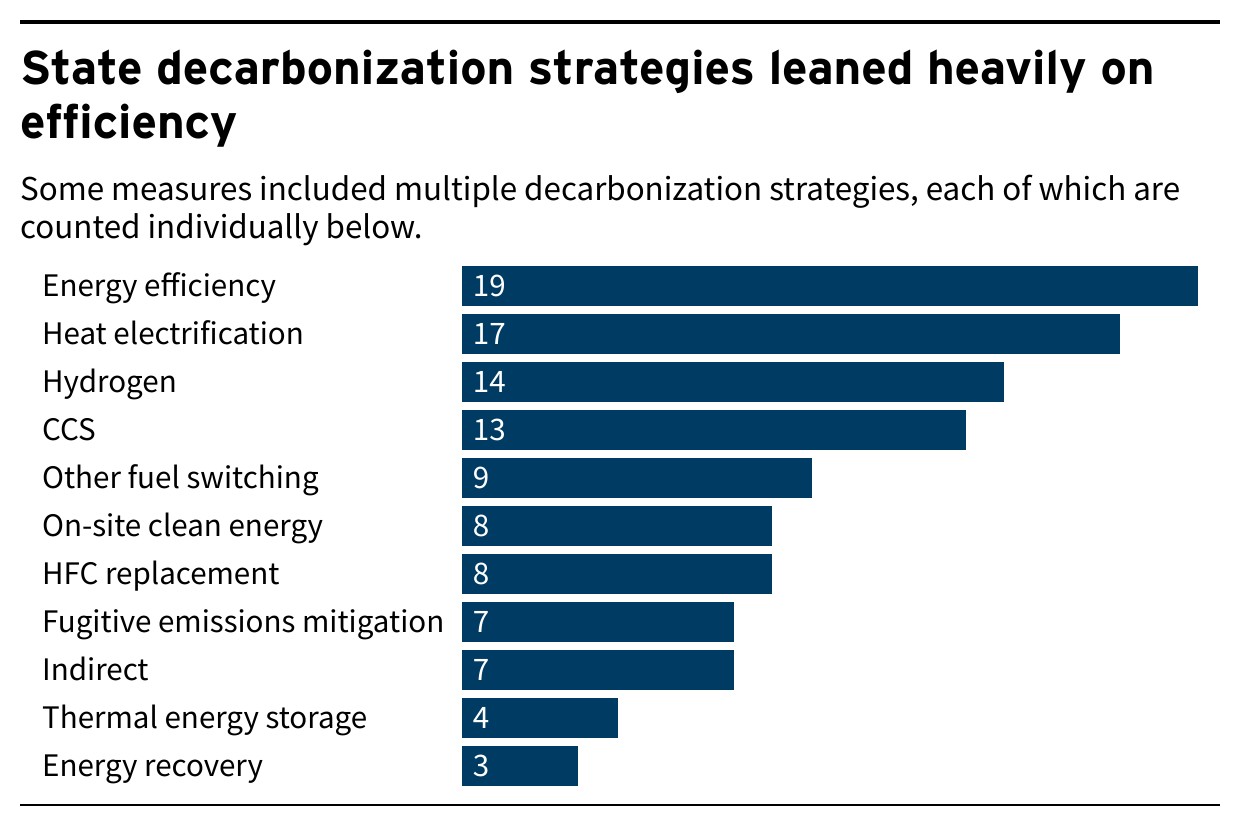

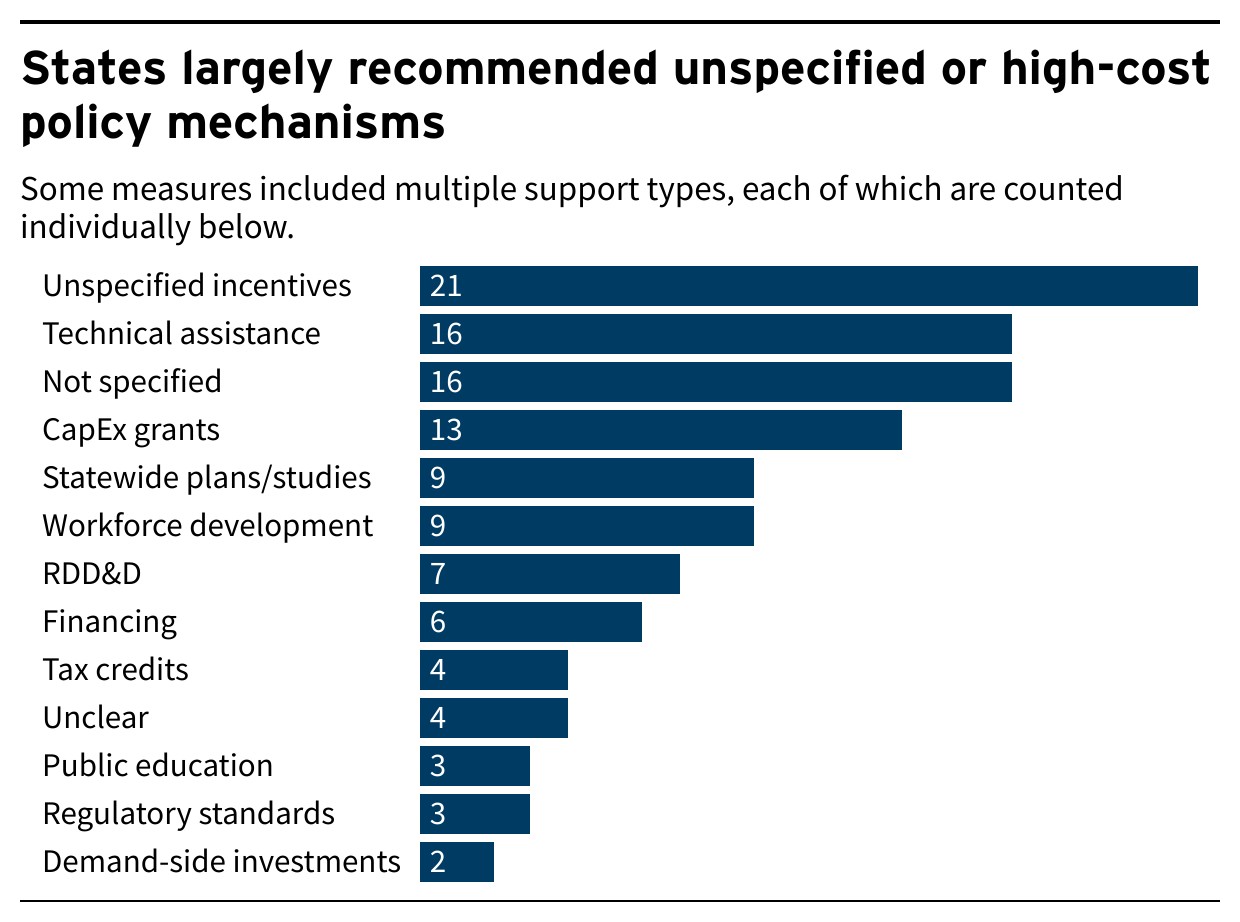

Where they do provide more robust policy plans, many of the states surveyed focus on measures requiring significant funding. Potentially high-cost measures—the unspecified incentives; capital investment grants; research, development, demonstration, and deployment spending; and uncapped tax credits—comprise nearly 50 percent of all the specified industrial decarbonization policies states advanced. Another 40 percent of that subset focuses on enabling policies—technical assistance, statewide plans and studies, workforce development, and public education. Only a small fraction of the industrial measures focus on relatively low-cost, high-impact opportunities, like financing that directly supports decarbonization projects, and all of the plans leave other viable low- and moderate-cost tools on the table altogether, as described below.

States’ focus on higher-cost measures is understandable in light of the clear anticipation of federal funding support at the time of PCAP development, as plans were the first stage of their applications for major federal funding through the CPRG’s Implementation Grant program. Only nine states referenced non-federal funding sources for their industrial measures, and just seven included estimated budgets for their policy measures. Unfortunately, there is little indication that states can expect any new federal investment in industrial decarbonization. States cannot depend on continued federal dollars to support their industrial decarbonization projects and will need to adjust their plans accordingly.

States also frequently committed to providing technical assistance and fostering workforce development in their industrial measures. While these may be relatively low-budget options for state support, their effectiveness is dictated by the level of capacity and expertise that the state is able to offer. As mentioned above, the complexity of industrial facilities and the appropriate suite of decarbonization solutions are highly specialized, such that the type of generalized support typically provided by state energy offices might not be as useful or applicable in the industrial space. Some states did specify partnerships with local university engineering departments, a structure that has proven to be effective through programs like Penn State’s PennTAP, which is also a partner in Pennsylvania’s RISE PA industrial decarbonization program.

Recommendations

1. Reconsider the highest and best use of funds for industrial decarbonization

State leaders should evaluate their industrial measures while bearing in mind the resources at their disposal, especially in light of limited federal investments. Those with cap-and-trade programs, for example, may have more climate funding available to budget than their peers. States able to avail themselves of the federal tax credits that currently remain on the books, including the Advanced Manufacturing Production credits, can likewise take advantage of the additional resources. But between limited federal support and the need to balance budgets, state leaders should begin by exploring the full suite of industrial policy tools to identify the most cost-effective solutions for their major industries.

2. Operate with the understanding that the most expensive programs are not always the highest impact

State policymakers should understand that lower-cost initiatives will often result in greater pollution reductions and increased savings for industry. For example, despite being the third-most recommended state support strategy, policy measures targeting capital costs are not always the best option. In fact, a 2024 study prepared for the Center for Applied Environmental Law and Policy found that policy measures targeting operating costs (like a Production Tax Credit) are more effective for industrial decarbonization than those targeting investment costs. The number and type of facilities in the state can shape the state support strategy as well; if a state’s industrial landscape is dominated by a handful of large plants, the program structure and award size should look very different than that in a state with dozens or hundreds of small- and medium-sized manufacturers. Either way, offsetting private costs is something that not many states will have the funds or political will to tackle.

3. Offer low-interest capital to industrial facilities that invest in low-carbon equipment

Many low-carbon technologies incur relatively rapid return on investment—and even when they don’t, states have the unique ability to offer more patient capital than what a company might find with a private lender. Several states established State Energy Financing Institutions (SEFI) over the last two years, with the intention of leveraging state dollars to bring federal Loan Programs Office (LPO) financing to their state. While the future of the LPO program is uncertain under the new administration, the pipelines of potential projects that these SEFIs identified can still be financed, with private investments filling the federal gap in the capital stack.

4. Implement regulatory and standards-based policies

Regulatory and standards-based policies offer another approach to limit upfront costs. Colorado’s air quality commission, for example, promulgated rules in 2021 and 2023 to reduce point-source emissions in their state’s manufacturing sector. Together the rules, called Greenhouse Gas Emissions and Energy Management for Manufacturing 1 and 2 (GEMM 1 and 2), mandate a 20 percent reduction in industrial emissions by 2030, compared to 2015 levels. The state has further backstopped these standards with capital grants, tax credits, and a credit trading scheme to help facilities reach compliance and encourage early action. Colorado’s example demonstrates the untapped potential of regulatory standards and the clear synergies between regulation and direct investment.

5. Cost-effectively ensure that industrial decarbonization improves regional grid stability

Impacts of the clean transition will ripple through the power grid and can either create additional strain or provide a variety of grid services if adequately planned for and incentivized. Providing industrial access to wholesale electricity rates, for example, can allow these facilities to use excess renewables that would otherwise be curtailed during off-peak hours, reducing operational costs and improving the efficiency and reliability of the grid. Additionally, industrial facilities often have a more flexible load shape than residential and commercial buildings and are better able to respond to dynamic pricing by shifting load. If offered the right utility incentives for on-site generation, thermal storage, and demand response, industrial facilities can serve as valuable contributors to the state’s distributed energy resources during valleys in utility generation, rather than an additional electrical demand.

6. Approach technical assistance with intention

Those states committed to offering technical assistance (TA) should be intentional about the type of support they are best able to facilitate. Illinois was one of only 13 states awarded an Implementation Grant from the EPA to implement their PCAP—their industrial strategy includes a “Clean Industry Concierge” program, which connects industrial facilities with third-party resources and facilitates stakeholder engagement. This approach takes advantage of the state’s centralized and neutral role, rather than attempting to provide custom-engineered solutions for individual facilities. Basic site pre-assessments and energy audits designed to go beyond the industry-standard efficiency assessments (which are driven solely or predominately by cost savings) can further optimize state TA efforts. States can also play a valuable role in registering and hosting efficiency consultants and technology providers within a single consultant portal, and aggregating demand-side orders (such as e-boilers and heat pumps) from small and medium-sized manufacturers in order to access bulk order discounts.

States Should Emphasize Industrial Decarbonization’s Co-Benefits

American industry’s reliance on oil and gas is far more than a climate issue: The sector’s fossil fuel dependence is a grave public health threat and a hindrance to international competitiveness. On the other side of that coin, the transition to cleaner industry could cut costs for manufacturers and reinvigorate industrial communities. These are all key arguments for state governments to facilitate industrial decarbonization—but the majority of the PCAPs surveyed do not make that case.

State Plan Trends

On the public health front, only half of the PCAPs studied identify potential co-pollutant reductions from their industrial decarbonization measures. Industrial co-pollutants—including NOx, ozone, and small particulate matter (PM2.5)—are responsible for higher rates of respiratory illness, heart disease, and cancer for both fenceline communities and the workers onsite. When states overlook the potential for co-pollutant abatement in their industrial decarbonization scoping, they risk deprioritizing the measures that would bring the biggest benefits to local air quality and community health. Co-pollutant reductions are a key consideration for industrial decarbonization policy.

Along similar lines, states can do more to promote the local economic benefits of their industrial decarbonization initiatives. Less than a third of the states surveyed mention job impacts in their industrial measures, and only 28 percent name workforce development as a key policy priority. Only 20 percent of the surveyed states mention partnering with organized labor to build the needed workforce and maintain job quality in the clean industry transition. But it’s clear that cleaner industry is a meaningful opportunity to maintain and create jobs; the necessary construction for wide-scale retrofits alone implicates nearly a dozen occupations and skilled trades, including electricians, carpenters, boilermakers, and others. Workers in transitioning facilities may also need reskilling to maintain and operate new equipment. These new and maintained jobs are a significant boon to industrial communities, and state leaders have the ability to more actively consider the economic development opportunities afforded by their industrial climate measures.

Industrial decarbonization will also be vital for keeping many manufacturers competitive—but by and large, the state plans studied do not identify that growing market imperative. Polluting industrial sectors with exports to Europe will soon face a significant trade barrier in the European Union’s carbon border adjustment mechanism, which will levy tariffs in proportion to the carbon emissions associated with imported products. With China accelerating its industrial decarbonization timelines, American producers must begin planning emissions reductions in order to compete. Initiatives like the First Movers Coalition, which has generated commitments to $16 billion of annual clean procurement by 2030, signal market interest shifting toward lower-carbon industrial products. States need to grapple with these trends as they consider whether and how to address industrial pollution.

Recommendations

1. Factor the full range of co-benefits into industrial decarbonization planning

Across the board, states can better emphasize industrial decarbonization’s co-benefits. Cutting industrial pollution can reduce disease and save lives, create and maintain good union jobs, cut manufacturers’ costs, and secure their competitiveness in a rapidly greening global economy, and enhance grid resilience. But the surveyed plans’ industrial measures don’t reflect this range of co-benefits.

That’s a missed opportunity—vocally promoting the downstream benefits of cutting industrial pollution could help secure stakeholder buy-in, facilitate local permit approvals, and build political will behind more ambitious initiatives. Incorporating those co-benefits going forward would ensure that key decisionmakers are aware of the industrial measures’ full value proposition.

2. Carry Justice40 forward

Though the federal Justice40 program has been shut down, the concept of allocating a portion of climate funding for environmental justice communities originated at the state level. States can use this opportunity to affirm their commitment to carrying Justice40 forward through all of their climate initiatives—including programs for industrial decarbonization. Doing so would ensure that the benefits of industrial decarbonization flow directly to fenceline communities and alleviate toxic pollution burdens on the people living there.

3. Encourage the use of community benefits plans

States can further ensure that fenceline communities benefit from industrial decarbonization by incentivizing or requiring community benefits plans for state-supported projects. Community benefits plans (CBP) requirements, as demonstrated by the U.S. Department of Energy, give local stakeholders a voice in the development and execution of industrial decarbonization projects. CBPs facilitate collaboration between manufacturers and the communities in which their facilities are sited, giving nearby residents the opportunity to advocate for investments in job training, local infrastructure improvements, and much more.

4. Holistically map workforce needs and partner with unions to implement industrial measures

States can complement community-focused measures by engaging directly with the workforce impacts of industrial decarbonization. Assessing the specific occupations implicated by their industrial measures—and making concrete commitments to grow that workforce in partnership with building trades unions—would substantially strengthen any state’s industrial decarbonization planning and take full advantage of the opportunity for local economic development. If states don’t anticipate workforce needs, the opportunity to create good union jobs through industrial measures may evolve into a bottleneck for progress as companies face worker shortages. Proactive planning and resourcing is vital.

5. Design policy with co-benefits in mind

To fully seize the generational opportunity industrial decarbonization presents, state governments should design their policy interventions to support decarbonization strategies with significant co-benefits. Industrial measures can create good jobs, shore up American competitiveness, invest in disadvantaged communities, and stabilize the grid. Maximizing these co-benefits for industrial stakeholders and the communities they sustain must mean intentional policy planning for the local economic context.

Turning State Commitments into Action

As technologies mature and the market imperative to decarbonize grows, states have a historic opportunity to lead the way in industrial decarbonization. The PCAPs studied here show clearly that state leaders are ready to take on that mantle. We recommend a series of refinements to maximize pollution reductions, invest in regional and local economic development, and seize every opportunity presented by industrial decarbonization. States have demonstrated a commitment to smart, targeted climate policy. This is their moment to deliver.